Aerospace Sealing Solutions

With decades of expertise, Sealing Devices excels in providing premier sealing solutions for aerospace operations, including both aircraft and space applications. Our AMS-certified seals are engineered to meet the extreme demands of the aerospace industry, ensuring reliability in the harshest conditions — from the high altitudes of aircraft operations to the cold vacuum of space.

Seals used in aerospace and space systems must withstand extreme temperature variations, high pressures, and full vacuum environments. Our cutting-edge materials and sealing technologies meet the evolving demands of the industry, supporting both commercial and defense aviation, satellite systems, and space exploration missions.

Advanced Aerospace & Space Sealing Solutions

Aircraft & Aviation Applications

Sealing Devices provides high-performance sealing materials that ensure reliability in critical aircraft systems, with solutions for:

- Engine Seals – Withstanding extreme heat and pressure while sealing fuel, air, and lubricants in aerospace engines.

- Fuel Systems – Preventing leaks and chemical degradation from aviation fuels, ensuring safety and efficiency.

- Hydraulic & Pneumatic Systems – Seals designed for landing gear, braking systems, and flight control components, operating across extreme pressures and temperatures.

- Gas Engine Turbines – Maintaining sealing integrity in high-temperature, high-pressure turbine environments.

- Cabin Pressurization & Air Conditioning – Ensuring airtight performance for passenger comfort and safety.

Our AMS-certified sealing solutions include O-rings, gaskets, and elastomers designed to perform reliably at temperatures as low as -65°F, meeting industry standards such as AMS 25988 Type 1, M25988/4-117, AMS 7276, AMS 3304, and AMS 3337.

Space & Satellite Applications

Beyond aviation, Sealing Devices engineers sealing solutions for the extreme conditions of space and satellite systems. Our space-rated seals and materials meet NASA, ESA, and MIL-SPEC standards to ensure longevity and integrity in vacuum environments, radiation exposure, and extreme thermal cycles.

Our sealing solutions for spacecraft, satellites, and propulsion systems include:

- Vacuum Seals – Ensuring airtight performance in space’s harsh vacuum.

- Thermal Seals – Withstanding extreme temperature swings in orbit.

- Radiation-Resistant Materials – Designed for high-radiation environments to maintain long-term integrity.

- Venting Solutions – Preventing pressure buildup in electronic enclosures.

- EMI/RFI Shielding – Protecting sensitive components from electromagnetic interference.

- Ablative (Heat-Resistant) Seals – Designed to withstand extreme heat by gradually eroding in a controlled manner, protecting spacecraft structures during re-entry and propulsion system operation.

Whether for aircraft or space missions, Sealing Devices delivers mission-critical reliability, helping engineers and aerospace leaders develop safer, more efficient, and longer-lasting aerospace and space systems.

Commitment to Quality and Innovation

At Sealing Devices, our AS9100 certification underscores our dedication to the highest standards of manufacturing and quality control, ensuring our seals meet the rigorous specifications required for both aerospace and space applications.

We collaborate with top aerospace and space exploration partners to provide custom-engineered solutions that enhance the safety, performance, and reliability of aircraft, spacecraft, and satellites.

Aerospace Sealing Devices

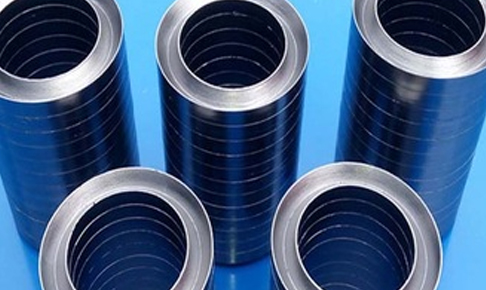

O-Rings

O-rings from Parker’s O-ring and Engineered Seals Division are available in both standard and metric sizes.

Gaskets

Die-cut gaskets and industrial gaskets are available for needs of temperature, chemical compatibility, pressure and more.

GORE Vents

GORE vents let sealed enclosures breathe, allowing airflow in and out, and improve enclosure failed seals performance.

Molded Rubber Parts

Custom molded rubber parts made in the US have several advantages and are available for compression, transfer, and injection molding.

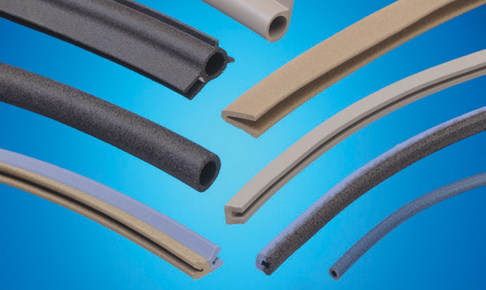

Sponge Cellular Foams

When designed for the application, sponge is an ideal solution for sealing out harsh environmental elements to help engineers meet IP specifications.

EMI Shielding

We offer EMI shielding O-rings and EMI conductive gaskets for ruggedized and outdoor EMI applications.

Thermal Management

We provide Thermal Interface Materials from Parker Chomerics. These materials have been designed into many applications.

Fluid Power Seals

Sealing Devices offers Parker spring-energized seals for diverse fluid power seal applications.

Why Choose Sealing Devices For Your Aerospace Sealing Solutions?

Industry Expertise: With more than 60 years of experience in the sealing and gasket industry, we excel at providing premier sealing solutions for aerospace applications.

Custom Solutions: We recognize that each application is unique. Our team of application engineers collaborate closely with you to craft custom aerospace sealing solutions that meet your specific requirements. Whether it’s a specialized form factor or a unique performance criteria, we have the expertise to deliver exactly what you need.

Quality Assurance: With ISO 9001:2015 and AS9100D certifications, our commitment to quality is assured. We use top-tier materials and rigorous testing to ensure reliable performance under tough conditions. As an ITAR-registered company, our aerospace sealing solutions offer long-term protection and peace of mind.

Customer Support: Our application engineers are available onsite to support the design of materials at the outset of your projects, ensuring solutions that perfectly align with your needs. Our design assistance includes material testing, in-house tool design, and more.

Discover Reliable Aerospace Sealing Solutions Solutions Today

Partner with Sealing Devices to ensure your systems are protected with our aerospace sealing solutions. Contact us today to explore customized that ensure dependable performance and long-lasting durability for your critical equipment.