Why are customers changing over to VX065?

It is the only AMS7410 solution right now. VX065 handles lower temperatures than other elastomers, but still has chemical resistance, compression set resistance, and offer elastomer rubber resiliency unmatched by other solutions. It is a technological advance that competitors are definitely chasing.

One misnomer of the VX065 is cost. The elastomer has a higher cost, but when reviewed against longevity of service hours and installation labor costs, it is highly cost competitive and proves itself with lower maintenance costs.

Stand alone Features:

- Only AMS-7410 QPL Listed for Custom Seals and O-Rings

- Wide Temperature Range: -65°F to 400°F (-54°C to 204°C)

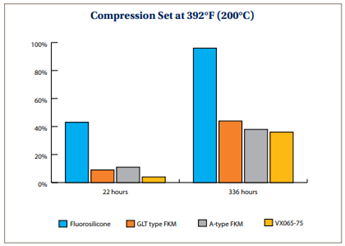

- Excellent Compression Set Resistance

- Extreme Low Temperature Performance

- Excellent Jet Fuel Compatibility

- Excellent High Thermal Stability Oil Compatibility

- Longer Seal Life

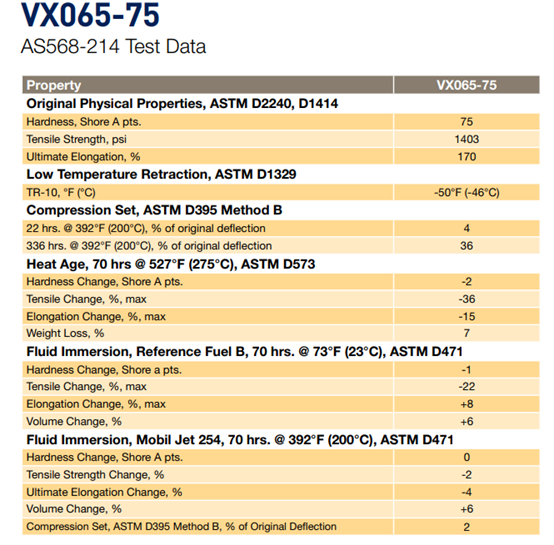

- VX065-75 Shore A Durometer

- VX365-90 Shore A Durometer for higher load or extrusion-resistance requirements

Form Options:

Strong Chemical Capability beyond typical FKM compounds:

VX065 can be molded into a variety of seal geometries to match your application:

- Molded standard O-rings

- Diamond seals

- D-shaped profiles

- Custom molded shapes

Chemical Compatibility Beyond Typical FKM

Parker’s VX065 compound offers strong chemical resistance beyond that of typical FKM materials, making it suitable for a wide range of fluids and environments, including:

- Mineral oils and greases

- IRM 901, IRM 902, and IRM 903 oils

- Nonflammable hydraulic fluids

- Silicone oils and greases

- Propane, butane, and natural gas

- Aromatic hydrocarbons such as benzene and toluene

- Halogenated solvents including trichloroethylene and carbon tetrachloride

- Gasoline

- High vacuum environments

- Ozone and other weathering exposures

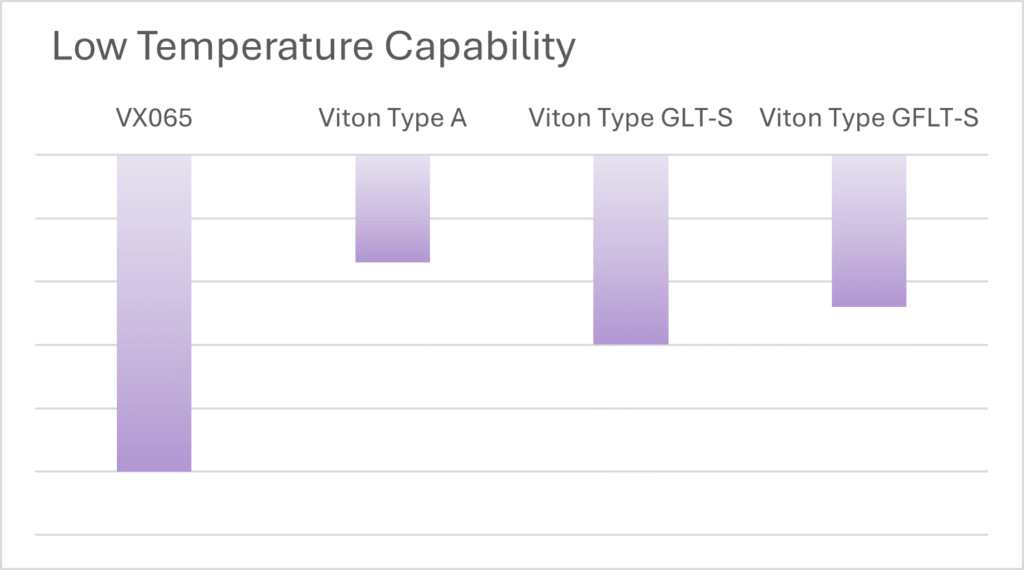

For Temperature here is a comparison of TR10 values:

Parker’s VX065-75 sets a new standard for low temperature FKM while still offering a high end capability.

Ready to see if Parker VX065-75 is the right fit for your program?

Contact Sealing Devices to review your aerospace sealing requirements, compare material options, or request VX065-75 samples for your next build.