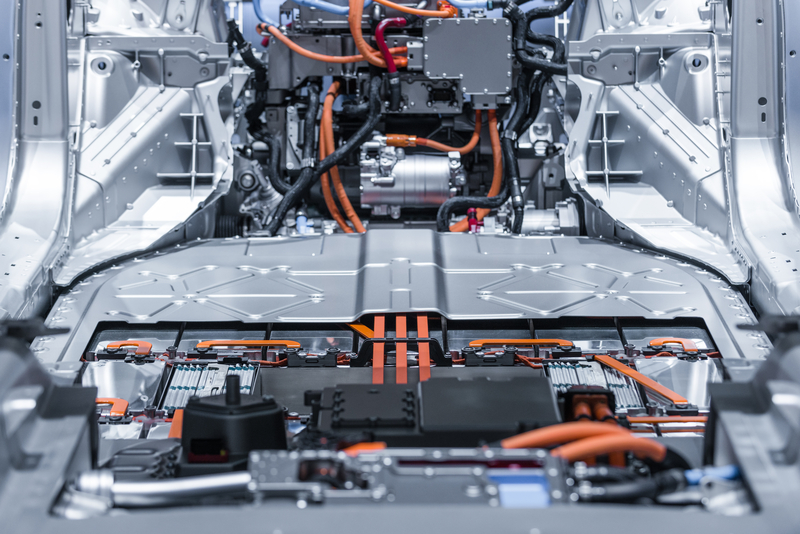

Global pressure to reduce carbon emissions is driving the current vehicle electrification trend, but not just in the automotive market. Aerospace, rail, and marine vehicle manufacturers are also introducing new, cleaner electric options in their respective spaces. This push across the various transportation sectors presents new challenges to those manufacturers and their supply bases. In order for electric vehicles (EVs) of all types to compete successfully against their current fossil-fueled counterparts, they must be effective and efficient in hauling goods and, more importantly, must be safe for passenger transportation. The design of the battery itself is the main contributor to those goals.

Here are some enclosure design considerations that are almost as crucial to ensuring that the whole electrical system works as intended:

Environmental Sealing:

Batteries must be protected from both natural and artificial water sources, such as rain and washdowns, to prevent the circuit from shorting out. Batteries should also be protected from solid particles to prevent electrical components from being contaminated, dislodged, or otherwise damaged. Gaskets can be made from a variety of materials depending on enclosure design, temperature range, and fluid exposure to protect the battery from failure by environmental forces.

Impact and Vibration Isolation:

Rotational energy is, quite literally, the driving force behind the engines that we use to move through the air, land, and water. However, rotating parts create near-constant vibration in the systems where they operate, which can lead to premature failures by placing repeated stresses on both mechanical and electrical components. Additionally, impacts from potholes in pavement or debris flung from roads can damage individual components or break their connections with others. Isolating the battery and other electrical elements with vibration-absorbing foam can protect the flow of electricity from being interrupted.

Thermal Management:

When in use, batteries produce heat that can degrade their performance over time and deform electrical contacts and other components which surround them. In extreme cases, damaged batteries may produce heat faster than it can naturally dissipate, which can cause ignition or explosion. Thermal interface materials exist to transfer heat from electrical components, such as batteries and computer chips, to heat sinks that are designed to allow for quick dissipation. There are also materials available to prevent excessive heat from transferring between battery cells, mitigating the risk of total failure.

Venting:

When charging, certain types of batteries produce hydrogen gas which is highly flammable and, if contained in high enough concentrations, can increase the risk of explosion. Allowing this gas to escape the battery enclosure while maintaining a water-tight seal can be a balancing act, but venting products are available to reduce the risk of failure by either of those means.

EMI Shielding:

Electromagnetic waves are caused by the flow of electrical current through a circuit, and all electrical systems have the ability to emit those waves. When the waves from one system reach another, they can cause electromagnetic interference (EMI). While this interference will not necessarily affect the performance of a battery, it can lead to failures in the systems that the battery powers; radio, GPS, WiFi/5G, and radar are all prone to EMI. Blocking and dissipating that interference using EMI shielding before it reaches sensitive electronics while maintaining an environmental seal is not only possible but necessary as autonomous vehicles become fully developed in both the consumer and commercial spaces.

Batteries are an integral part of today’s technological landscape, allowing for reliability in our 5G networks to freight trains alike. It is critical that enclosures adequately protect their respective batteries from all manner of hazards to ensure the longevity and safety of the vehicles which will soon surround us. For more information about Sealing Devices product solutions, or to discuss your specific EV application, please use the contact us link below to speak with our team of Applications Engineers.