Reliable access to voice and data communication has become a critical part of our daily lives. The Telecommunication systems we rely on are exposed to some of the harshest outdoor conditions. Equipment manufacturers must protect these sensitive systems from several environmental hazards to ensure performance and keep us connected.

Customer Problem: Most telecom products are mounted in high outdoor locations to increase signal transmission effectiveness, exposing them to unpredictable harsh weather conditions. These locations are often difficult to access for service, so to maintain system up time enclosures need to be built to withstand the stress of high altitudes, temperature changes and pressure differentials. If the equipment is not fully sealed, water and other contaminants can penetrate the enclosure, degrading sensitive internal electronics. When enclosures are subject to rapid temperature change, the resulting pressure differential created between the inside of a sealed enclosure and the exterior atmosphere will want to equalize, putting extreme stress on seals, mating joints, and connector points. Over time this stress will cause seals to degrade or fail, allowing dust and contaminants inside, even though the enclosure appeared fully sealed when launched.

Customer Requirements: Design effectively sealed enclosures that:

- Maintain reliable connectivity

- Decrease maintenance

- Meet equipment life expectancy

- Reduce manufacturing costs

Solution: The most effective way to increase product life, decrease failures, and ensure reliability of electronics in a sealed enclosure is to allow for pressure equalization between the internal and external environment via venting. This can be accomplished with Gore® Protective Vents.

HOW THEY WORK

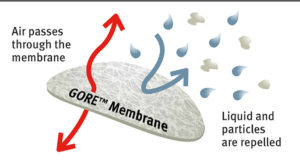

Gore® Protective Vents continuously reduce component stress by allowing sealed enclosures to “breathe”. The key is the Gore® expanded PTFE (ePTFE) membrane which allows for air transfer through the vent while preventing water or dust ingress into the sealed enclosure. When a pressure change occurs, air passes through the vent until pressure equalization is achieved. This constant air exchange helps reduce seal stress, and manage condensation, greatly extending product life. The vents come in a variety of types and sizes such as adhesive backed (sticker), screw-in, and snap-in. All provide a level of Ingress Protection (IP) including styles meeting IP69k.

Gore® Protective Vents continuously reduce component stress by allowing sealed enclosures to “breathe”. The key is the Gore® expanded PTFE (ePTFE) membrane which allows for air transfer through the vent while preventing water or dust ingress into the sealed enclosure. When a pressure change occurs, air passes through the vent until pressure equalization is achieved. This constant air exchange helps reduce seal stress, and manage condensation, greatly extending product life. The vents come in a variety of types and sizes such as adhesive backed (sticker), screw-in, and snap-in. All provide a level of Ingress Protection (IP) including styles meeting IP69k.

Conclusion: Telecommunication systems are critical to our daily lives. Equipment in this market needs to be designed to withstand the most extreme conditions to reliably function. Gore® Protective Vents, supplied by Sealing Devices enhance the sealing effectiveness of Telecom enclosures by:

- Reducing Seal Stress by providing continuous pressure equalization.

- Maintaining Sealing via its durable barrier against liquid, dust, dirt and other contaminants

- Reducing condensation by allowing water vapor to escape through the membrane

Let Sealing Devices collaborate on your next Telecom product, provide solutions that last a lifetime, and meet or exceed your project requirements. Contact us today for Gore® Vent information and allow our applications engineering team to make recommendations.