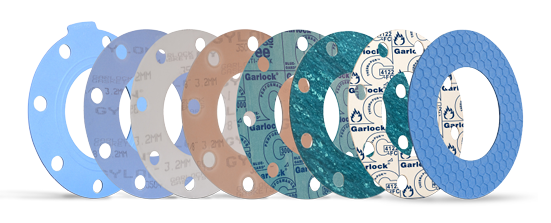

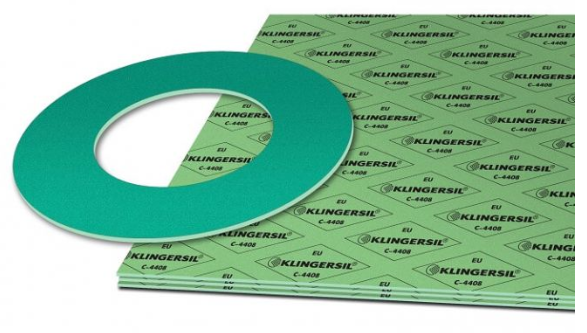

Transition from Asbestos to Safer Materials

Asbestos, once widely used in gaskets, was phased out due to recognized health hazards, leading to a need for safer alternatives. Companies like Garlock, Klinger, and Armstrong responded by developing asbestos-free materials with similar properties. These new materials incorporate fibers like Aramid, fiberglass, and synthetics, often blended with familiar gasket industry elastomers such as nitrile, neoprene, and EPDM. For high-temperature applications, graphite and Mica-based materials are common choices.

Benefits of Compressed Fiber Materials

Compressed Fiber materials offer a viable alternative when solid rubber isn’t suitable due to factors like temperature, pressure, or media exposure. Some of these materials can endure:

- Temperatures as high as 1,800 degrees Fahrenheit

- Impressive compressive strength, with a maximum load capacity of 15,000 psi.

These characteristics make them ideal for high-pressure applications in industries like chemical processing, oil and gas, power generation, pulp and paper, microelectronics, and transportation.

Material Sizes and Processing at Sealing Devices

These materials typically come in 60” x 120” or 60” x 60” sheets, which often cover most application sizes. At Sealing Devices, our extensive experience includes processing various types and thicknesses of compressed fiber sheet materials. We offer a range of options including:

- Standard ASME Flange Gaskets- traditional die-cut full face and ring gaskets

- Larger or custom gaskets: die-less cutting options available

- Oversized applications: gaskets can be segmented and installed like a puzzle

Additionally, we offer cost-effective solutions for custom manhole covers, replacing traditional metal gaskets.

Selecting the Right Gasket Material

Choosing the right gasket material begins with a clear understanding of your application’s requirements. Our team of Sealing Devices Application Engineers specializes in guiding customers through this process to identify the most suitable material for their specific needs. For more information or technical assistance with your next sealing challenge, please don’t hesitate to reach out to us today.