What Electrically Conductive Adhesives Offer

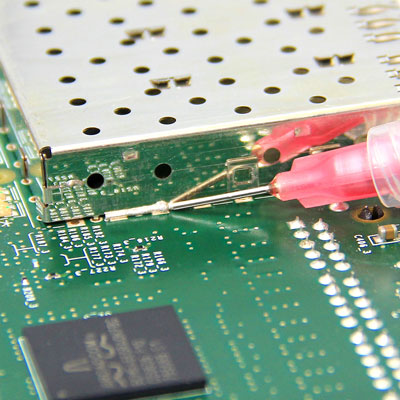

Electrically conductive adhesives and epoxies are specialized solutions designed to bond components and hold them in place while allowing electrical current to pass through. These adhesives are commonly used in electronic applications, providing strong adhesion, high conductivity, and minimal environmental impact.

These adhesives are ideal for applications where traditional fastening methods cannot be used or where a conductive path is required between components.

Features & Benefits

- Excellent Electrical Conductivity: These adhesives provide a reliable conductive path between components, ensuring the proper functioning of electronic systems.

- Strong Adhesion Properties: They offer robust bonding to a wide variety of surfaces in demanding conditions.

- No Volatile Organic Compounds (VOCs): Free from harmful chemicals and corrosive by-products, these adhesives are safer for both the user and the environment.

- Thermal Stability: Withstands temperature variations without losing performance.

- Versatile Applications: Suitable for use in a wide range of industries and applications, they deliver consistent performance across various environmental conditions.

Potential Applications & Industries

Electrically conductive adhesives ensure reliable performance across various applications. They support sensitive electronic components in machinery, communication devices, fluid power systems, energy storage systems, and more. In these systems, they’re most often used for gap filling, bonding components, sealing electrical enclosures, and EMI venting.

These adhesives are designed for the electronics industry, but are often used in applications across industrial, aerospace, military, transportation, battery, and similar industries as well. Their ability to bond and conduct electricity makes them a critical component in the manufacturing of electrical devices, vehicle systems, and advanced electronics.

Design Specifics & How The Product Works

Electrically conductive adhesives are available in various filler and binder combinations, offering tailored solutions for different electrical and mechanical needs. They ensure long-term durability, optimal conductivity, and a strong bond, even in harsh conditions.

What Makes Electrically Conductive Adhesives So Effective? These electrically conductive adhesives are designed for strong adhesion and to provide an effective conductive path, enabling electronic components to function properly without the need for traditional mechanical connections. Their resistance to environmental stressors ensures longevity and reliability.

Products Bought With Electrically Conductive Adhesives

Conductive Foam Sheet

Silicone foam offering electrical conductivity for shielding and grounding.

1075 (Conductive Silicone)

Conductive silicone for sealing and bonding with excellent thermal and electrical properties.

Connector Gaskets

Gaskets designed to seal and provide conductivity for secure electrical connections.

Form-in-Place Gaskets

Customizable conductive sealing solution for precise, reliable barriers.

Our Value Added Services

At Sealing Devices, we provide more than just high-quality conductive adhesives. We work closely with our clients to ensure the best fit for their specific needs, and our Application Engineers work closely with you to deliver optimal performance. Whether you need custom adhesives, scalable production, or help with integration, we ensure the right product and service for your application.