What Spring Energized Seals Offer

Spring-Energized Seals provide reliable, high-performance sealing solutions for fluid power equipment, such as hydraulic and pneumatic systems. These seals feature a spring between the sealing lips to maintain constant contact with sealing surfaces, ensuring a tight seal under various pressure conditions.

Available in multiple materials and profiles, Spring-Energized Seals can be customized to meet specific application needs, including high temperatures, extreme pressure, and low friction requirements.

Features & Benefits

- Reliable Sealing in No Pressure and Vacuum Applications: Effective even in low-pressure or vacuum environments.

- Pressure Resistance: Withstands pressures up to 10,000 psi.

- Wide Temperature Range: Suitable for temperatures from -450°F to 600°F (-268°C to 316°C).

- Varied Profile Features: Improves sealability, reduces friction, and scrapes surface contamination.

- Material Options: Available in Virgin PTFE, Filled PTFE, Hytrel® Elastomer, and UHMW Polyethylene.

- Multiple Fillers for Enhanced Performance: Includes low friction, low wear, broad temperature resistance, chemical compatibility, and antimicrobial properties.

- Multiple Spring Configurations: Canted Coil (low spring load), Cantilever (medium spring load), and Helical Coil (high spring load).

Spring-Energized Seals offer an optimal balance of durability, versatility, and performance for a wide range of sealing applications, especially in extreme conditions.

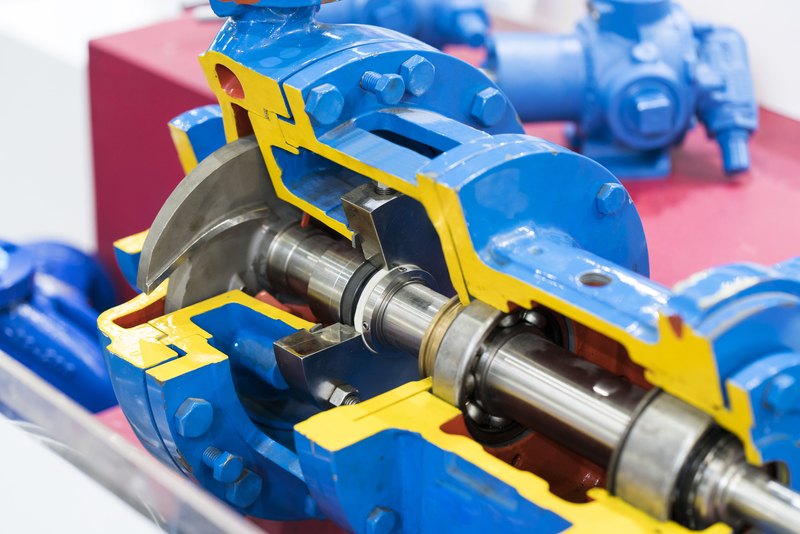

Design Specifics & How The Product Works

Spring-Energized Seals consist of a sealing element, typically made of PTFE, which is energized by a spring. This design ensures constant contact with the sealing surfaces, providing effective sealing performance even in high-pressure or low-pressure environments. The spring helps the seal maintain consistent pressure against the sealing surfaces, compensating for wear and temperature fluctuations. These seals can be tailored for specific applications, whether in static or dynamic environments.

What Makes Spring Energized Seals So Effective? The effectiveness of Spring-Energized Seals lies in their ability to provide constant sealing force, even in the absence of pressure, thanks to the energizing spring. This feature allows them to maintain a reliable seal in extreme environments with high temperatures, high pressure, or vacuum conditions.

Additionally, the choice of materials, such as PTFE and Hytrel®, combined with different spring configurations, enables these seals to offer low friction, minimal wear, and excellent resistance to chemicals and temperature variations, making them versatile and dependable in various applications.

Products Bought With Spring Energized Seals

Oil Seals

Seals that close the gap between rotating and non-rotating parts in machinery, preventing fluid leaks and protecting against contaminants.

Hydraulic Seals

Seals designed to retain hydraulic fluids, excluding contaminants, to maintain hydraulic pressure.

Our Value Added Services

At Sealing Devices, we go beyond providing high-quality Spring-Energized Seals. Our experienced Application Engineers work closely with you to develop customized solutions, ensuring optimal performance in your specific sealing applications. Whether you need unique materials, specific spring configurations, or custom sizes, we are dedicated to providing solutions that meet your exact needs. Our goal is to ensure that your sealing systems remain reliable and efficient for the long term.