What Radial Shaft Seals Offer

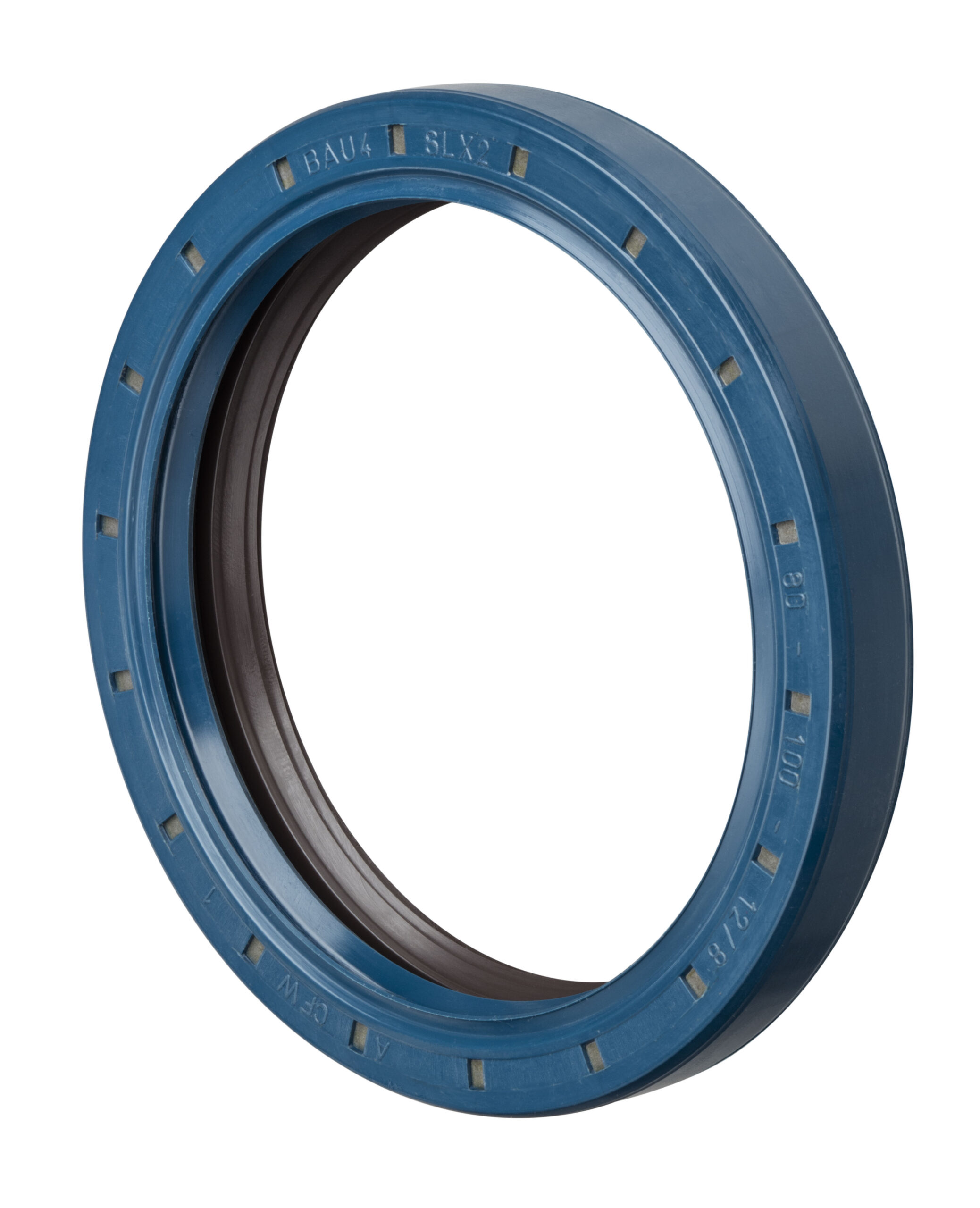

Radial shaft seals, often referred to as oil seals, are essential for sealing rotating machine elements. They function by closing the gap between rotating and non-rotating parts, preventing leakage of fluids while keeping contaminants out of the system.

By retaining fluids and preventing external contaminants, radial shaft seals protect vital components, enhancing the efficiency and longevity of machinery.

Features & Benefits:

- Versatility: Designed with a wide range of elastomers, materials, and configurations, these seals can handle varying pressures, media types, and temperature extremes.

- Low Friction: Reduces wear and prolongs service life by maintaining low friction during operation.

- Customization: Available in various sizes, materials, and designs to meet specific requirements, ensuring optimal performance in diverse environments.

- Temperature Resistance: Available in materials that can handle a broad temperature range, making them ideal for extreme conditions.

- Effective Sealing: Prevents contamination by sealing off dirt, dust, water, and other foreign materials from entering critical systems.

- Long-Lasting Durability: Designed for high pressure, long service intervals, and challenging working environments.

Radial shaft seals are engineered to handle high pressure, resist contamination, and perform under extreme temperatures and conditions.

Potential Applications & Industries

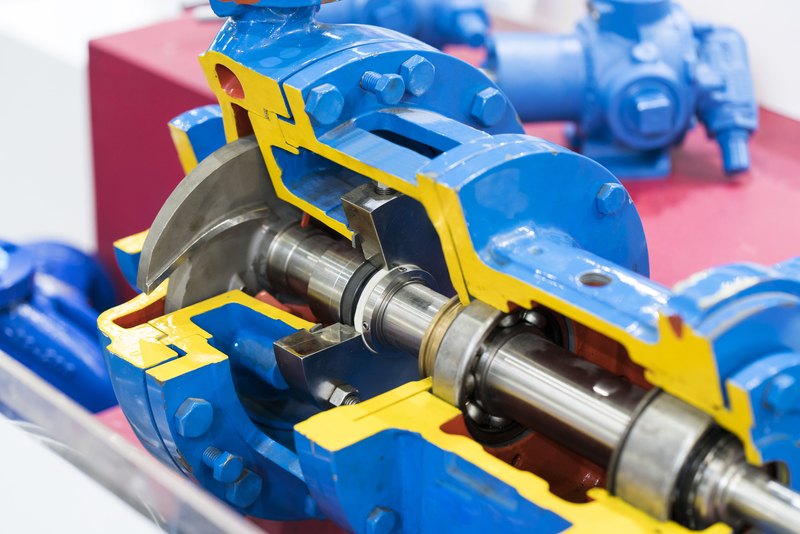

Radial shaft seals are used in industries where reliable sealing is essential for the longevity and efficiency of machinery. Common applications include sealing rotating shafts in hydraulic systems, pumps, gearboxes, automotive engines, and electric motors. These seals are critical in preventing leakage of oils and other fluids, protecting against contaminants, and maintaining pressure within the system. They’re especially effective in machinery where rotating elements must be tightly sealed without impeding motion.

Radial shaft seals are found in various industries that demand high-performance sealing solutions in challenging conditions. Key industries include fluid power, wind power, electronics, agriculture, construction, automotive, and industrial.

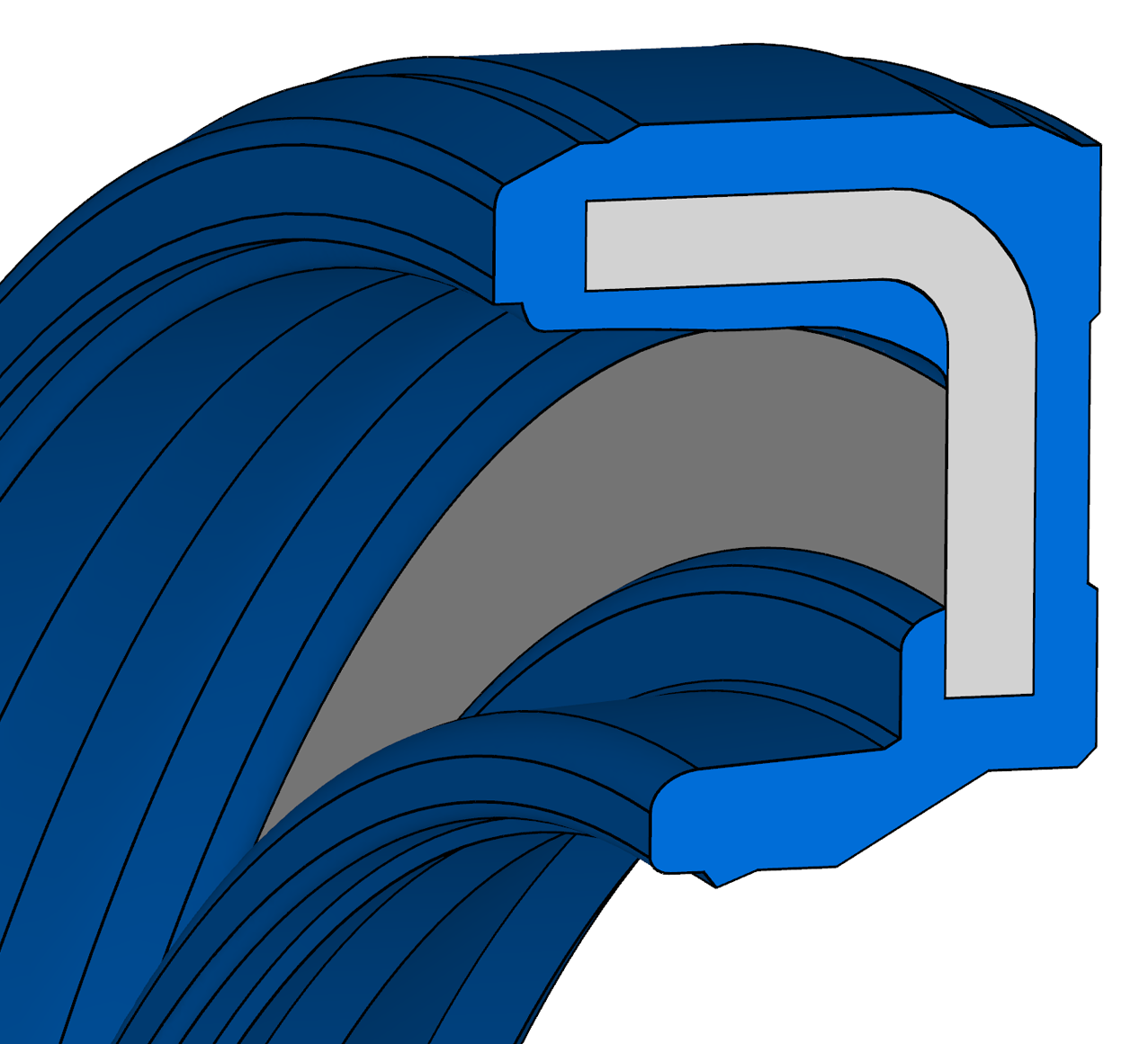

Design Specifics & How The Product Works

- Versatility: Designed with a wide range of elastomers, materials, and configurations, these seals can handle varying pressures, media types, and temperature extremes.

- Low Friction: Reduces wear and prolongs service life by maintaining low friction during operation.

- Customization: Available in various sizes, materials, and designs to meet specific requirements, ensuring optimal performance in diverse environments.

- Temperature Resistance: Available in materials that can handle a broad temperature range, making them ideal for extreme conditions.

- Effective Sealing: Prevents contamination by sealing off dirt, dust, water, and other foreign materials from entering critical systems.

- Long-Lasting Durability: Designed for high pressure, long service intervals, and challenging working environments.

Radial shaft seals are engineered to handle high pressure, resist contamination, and perform under extreme temperatures and conditions.

What Makes Radial Shaft Seals So Effective? Radial shaft seals feature a unique design that maintains sealing integrity under both static and dynamic conditions, which is critical for long-term reliability. Radial shaft seals excel in environments with high pressures, extreme temperatures, and exposure to aggressive fluids.

Key Types of Radial Shaft Seals:

Rubber-cased

Rubber-cased seals are the most common kind of radial shaft seals, these types of seals offer a lot of versatility as the elastomers can expand and contract. Thanks to the variety of elastomers able to be used they can handle high pressures, a variety of media and don’t pose the risk of rust with metal-cased seals.

Metal-cased

Are a more cost-efficient solution and are designed to expand and contract equally during operations and provide rigidity. These seals have a higher risk of rust and generally aren’t as versatile as other type of radial shaft seals.

Premium Sine Seal (PSS)

This unique design by Freudenberg-NOK Sealing Technology increases reliability, reduces friction, power loss and actively counteracts internal contamination inside of the sealing system. These seals provide the benefits of both rubber and metal-clad seals with the rigidity and ability to handle high pressures and media.

Cassette Seals

Consist of a radial shaft seal and an optimized wear sleeve. Thanks to this combination they are capable of withstanding high stresses which makes them a great solution in heavy construction, agriculture, and transmissions among other applications. With the wipers, they protect against dirt, water, and other environmental influences.

Most Common Materials:

Nitrile Butadiene Rubber (NBR)

Ideal performance -22°F to +212°F (-30°C to +100°C), offers mechanical strength with a high elasticity and deformation resistance. NBR performs well in fatty media, oils, and fuels.

Fluoroelastomer (FKM)

Ideal performance -13°F to +392°F (-25°C to +200°C), offers excellent to chemicals, fuels, fats and mineral oils.

Polytetrafluoroethylene (PTFE)

Ideal performance -328°F to +500°F (-200°C to +260°C), in addition to its exceptional performance in a massive temperature range PTFE also offers a truly exceptional media compatibility.

Silicone (VMQ)

Ideal performance -58°F to +450°F (-50°C to +232°C), and are resistant to ozone, oils, fats, and UV radiation.

Products Bought With Radial Shaft Seals

Spring Energized Lip Seals

Seals that use a spring to maintain constant pressure for optimal performance in demanding applications.

Flange Seals

Sealing solutions made from compressed fiber (Garlock 3000 or 2950) or spiral wound for high-pressure and temperature applications.

Labyrinth Seals

Non-contact seals that prevent contaminants from entering rotating machinery while maintaining low friction.

Mechanical Seals

Used to prevent leakage in rotating equipment, offering effective sealing under pressure and temperature conditions.

Pump Packing – Braided Rope

Reliable sealing material used for pumps to prevent fluid leakage in rotating equipment.

Our Value Added Services

At Sealing Devices, we take pride in offering more than just premium radial shaft seals — we provide expert guidance and support every step of the way. Our Application Engineers collaborate with you to determine the best sealing solution based on your unique requirements. Whether it’s optimizing for high temperatures, pressures, or specific media compatibility, we help you choose the right materials and configurations. Our team is committed to delivering tailored solutions for challenging applications, ensuring your systems perform efficiently and reliably.