Satellite Sealing Solutions for Aerospace at Satellite 2025

March 10-13 – Washington, DC

Sealing Devices is a trusted partner for aerospace and satellite industries, providing high-performance sealing solutions that meet the most demanding specifications.

Discover our full range of aerospace sealing solutions, including advanced materials designed for space environments, thermal management, EMI shielding, and more.

Learn More About Our Aerospace Solutions:

-

- Aerospace Sealing Solutions Page – Learn about our custom-engineered O-rings, gaskets, and more for both aircraft and space applications.

- Request a Quote – Ready to discuss your sealing needs? Our team is here to provide tailored solutions for your specific requirements.

- Explore Our Products – Browse through our full range of sealing products for aerospace and satellite applications.

We invite you to get to know how Sealing Devices can support your next aerospace project with our high-performance sealing technologies. Visit our Aerospace Industry Page for more detailed information.

Common Application Requirements

- Low outgassing per NASA

- Low weight / light-weighting

- Extreme pressure changes, down to full vacuum

- Water/weather protection

- UV and ozone resistance

- Thermal management

- EMI shielding

- Extreme temperatures

Sealing Solutions

- O-Rings

- Die-cut gaskets (solid or cellular)

- EMI shielding elastomers and foams

- Thermal interface materials

- Protective Vents

- Adhesives, tapes, sealants, and potting compounds

Exclusive Demo at Satellite 2025: Radome Sealing Solutions

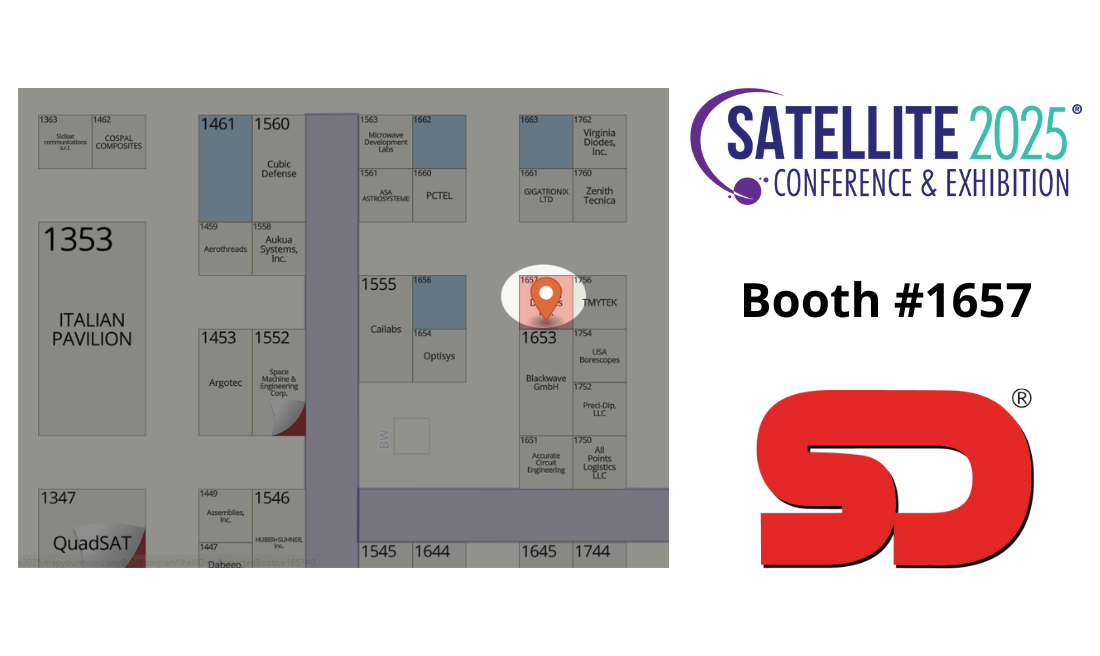

See our advanced Radome Sealing Solutions in action, exclusively at Satellite 2025 in Washington, DC. This demo highlights how our sealing and venting products meet the extreme demands of space and satellite applications. Visit Booth 1657 to speak with our engineers about how these solutions can elevate your projects. Can’t attend? Request a personalized demo or consultation with our experts today!

Engineering Resilience: Innovative Sealing and Venting Solutions for Aerospace Antennas

The demo unit shown here and at our Satellite 2025 booth was inspired by a recent project in which many of the same sealing and venting products were recommended for use in a functional radome.

Components Utilized in this Demo:

Gore® Threaded Protective Vent

- They rapidly equalize pressures within the enclosure, in response to pressure changes (due to changes in altitude or temperature — as with a sudden heavy rain). This reduces stress on housing components and reduces the risk of premature seal failure, or cracks in the housing itself.

- They release gases that form when electronics within the enclosure heat up. This prevents the gases from reaching dangerous concentrations.

GORE® Protective Vents can prevent damage to the sensitive electronics within the enclosure:

- They prevent contaminants like dust, dirt and liquids, fluids or oils from entering the enclosure.

- They reduce condensation build-up, and the potential for corrosion, by allowing water vapor to pass out of the enclosure.

- They release gases to the environment, protecting electronic components from gas contamination.

Parker Spring-Energized Lip Seal

PTFE spring-energized seals are ideal for rotary applications where low friction is needed for normal operation. The PTFE can be modified with several different filler materials to tailor the seal characteristics to your needs. Sealing Devices offers Parker FlexiSeals, as well as similar alternatives.

Check out the Parker Fluid Seal Design Guide for more information.

Rogers Bisco Closed-Cell Silicone Foam

Benefits

- Resistant to temperature extremes, UV and ozone

- Extremely resilient to mechanical fatigue

- Excellent compression-set and creep resistance

- Compliance with the most stringent UL flame ratings

- Manufactured in an AS-9100 ISO-9001:2015 certified facility

Parker Chomerics Conductive Elastomers

These elastomers are available as:

- Extruded cord stock that can be sold as cut lengths or bonded to form a continuous seal

- Molded sheets that can be die-cut for greater part complexity

- Finished molded parts that offer 3-dimensional geometry and tightly controlled tolerances

Parker Chomerics Conductive Open-Cell Sponge

Parker Chomerics Thermally Conductive Gap Fillers

These soft, highly conformable materials fill gaps of all sizes to improve heat conduction between heat-generating and heat-dissipating surfaces.

Your Engineering Challenges, Solved.

Facing a sealing dilemma in your latest project? Searching for a solution that meets your specific needs? Sealing Devices Inc. is here to turn those challenges into triumphs – for free.

Why Choose Sealing Devices?

At Sealing Devices Inc., we believe in creating solutions that are as unique as your problems. With decades of expertise in engineering high-performance sealing technologies, we’re not just vendors; we’re your partners in innovation. This year at Satellite 2025, we’re offering exclusive, complimentary solutions consultations to help you overcome your engineering obstacles.

How Does It Work?

1. Sign Up for a Free Consultation: Secure your spot for a one-on-one meeting with our expert solutions representatives at the Satellite 2025 Conference & Exhibition.

2. Send Us Your Challenge: Have a specific issue in mind? Email us with your problem and any relevant documentation before the show. We’ll come prepared with tailored solutions, just for you.

3. Meet Us at Satellite 2025: Prefer to discuss in person? Make an appointment and bring your challenge directly to our booth

(1657). Our team will work with you on-the-spot to troubleshoot and find the answers you need.

Ready to Transform Your Project?

Don’t let sealing challenges slow down your innovation. Whether you’re in the early stages of design or need a last-minute solution, we’re here to help. Here’s how you can get started:

-

- Email Your Challenge:

Got a specific issue? Email us with your problem. The more we know, the better we can prepare. - Visit Us at the Show:

Find us at Booth 1657 at the Satellite 2025 Conference and Exhibition. We’re ready to meet you!

- Email Your Challenge:

Visit Our Representatives

Melissa Prue

Territory Sales Manager

Melissa brings six years of valuable experience to our team. With an intimate understanding of various applications, she focuses on providing specialized sealing solutions for the aerospace, defense, and government prime sectors. Known for her responsiveness and customer-centric approach, Melissa is dedicated to diligently addressing and exceeding her clients’ needs. Her expertise in navigating complex requirements ensures that she delivers tailored, effective solutions. Contact Melissa for reliable support and expertise in achieving your specialized sealing goals.

About Us

Sealing Devices is a premier North American manufacturer of gaskets offering a variety of different methods to produce gasket products. Our manufacturing facility includes over 200-pieces of equipment and in-house tooling and die-making, which allow us to make gaskets from commercial and mil-spec rubber, compressed sheet gaskets, cloth inserted gaskets, paper, fabric, felt and most any other material with quick cut options.

New from our Suppliers

VIDEO: BRAND NEW! GORE® Thermal Insulation Crayon Demonstration

GORE® knows how to beat the heat! Check it out for yourself — crayons — with and without GORE Thermal Insulation — melting at different rates.

READ MORE about how GORE® is meeting growing thermal challenges in electronic devices using GORE® thermal insulation.

Parker Chomerics SOFT-SHIELD 3800

Learn about Parker Chomerics SOFT-SHIELD 3800, the electrically conductive fabric over silicone foam EMI shielding and electrical grounding gasket that’s taking the industry by storm!

With complex and unique non-rectangular shapes, this gasket is an extension of Parker Chomeric’s popular SOFT-SHIELD 3700 product.

And, it’s an ideal solution for applications exposed to high temperatures where a UL 94 V-0 requirement exists.

W.L. Gore’s Industrial AVP series Acoustic Vent Products

Key highlights include:

- Superior acoustic performance

- Versatile sizing, even for small components

- Reliable defense against water, dust, and other elements

- Capable of withstanding 2 meters underwater for an hour

- Handles water sprays of up to 26 gallons per minute from 8 ft away

- Silicone-based adhesive for added strength in extreme temperatures

Elastomeric Material Solutions for Air Transportation and Space Exploration

Rogers materials are trusted in many of the world’s commercial, aviation aerospace, and satellite applications.

From vibration dampening of cargo bins, to sound blocking in the cabin, to increasing battery efficiency for advanced mobility, Rogers

materials help to improve performance, safety, and passenger comfort.

Rethink Solutions for Bonding Composites and LSE Plastics

3M™ VHB™ Tape provides a flexible bond that allows for thermal expansion up to three times its thickness and is therefore ideal for joining dissimilar materials. It shows excellent dynamic stress performance that can even exceed certain structural bonds. By taking advantage of its ability to adhere to difficult-to-bond substrates, you can use lighter and thinner materials for groundbreaking innovations in form and function, supporting durability, aesthetics and weight reduction.

Recent advances in multi-material tapes and adhesives provide designers and manufacturers new assembly options beyond traditional mechanical and thermal assembly methods.

Our Suppliers

Superior Seals

Exceptional Service

Established Supplier relationships

for 60+ years

See what our Suppliers and Customers

are saying about working with us.

Why Sealing Devices

Since 1963, Sealing Devices has been a proud manufacturer, fabricator, and distributor of O-Rings, gaskets, EMI shielding, and thermal interface materials, custom molded rubber parts, protective vents, tapes, adhesives, and sealants for all types of sealing applications. We offer a one-stop shop for all of your seal and gasket needs:

- Applications Engineering Support

- One-to-One Customer Service Representation

- Vendor Managed Inventory

- State-Of-The-Art Quality Systems

- In-House Tooling and Machining Centers

- Experience with Most Sealing Materials